Internal reference resistors

Measurements are compensated against drift using four high precision, high stability internal reference resistors. During each sampling sequence, the PT12 measures each reference resistor to define the measuring range and accurately determine the unknown values of each of the 12 channels. The result of this specific reference resistor measurement technique is a significant reduction in overall uncertainty.

Selectable measuring currents

Depending on the thermometer resistance, up to three different measuring current strengths can be selected manually or automatically. The function is also useful for performing self-heating tests with different measuring currents, as required by guidelines (e.g. DKD-R 5-1).

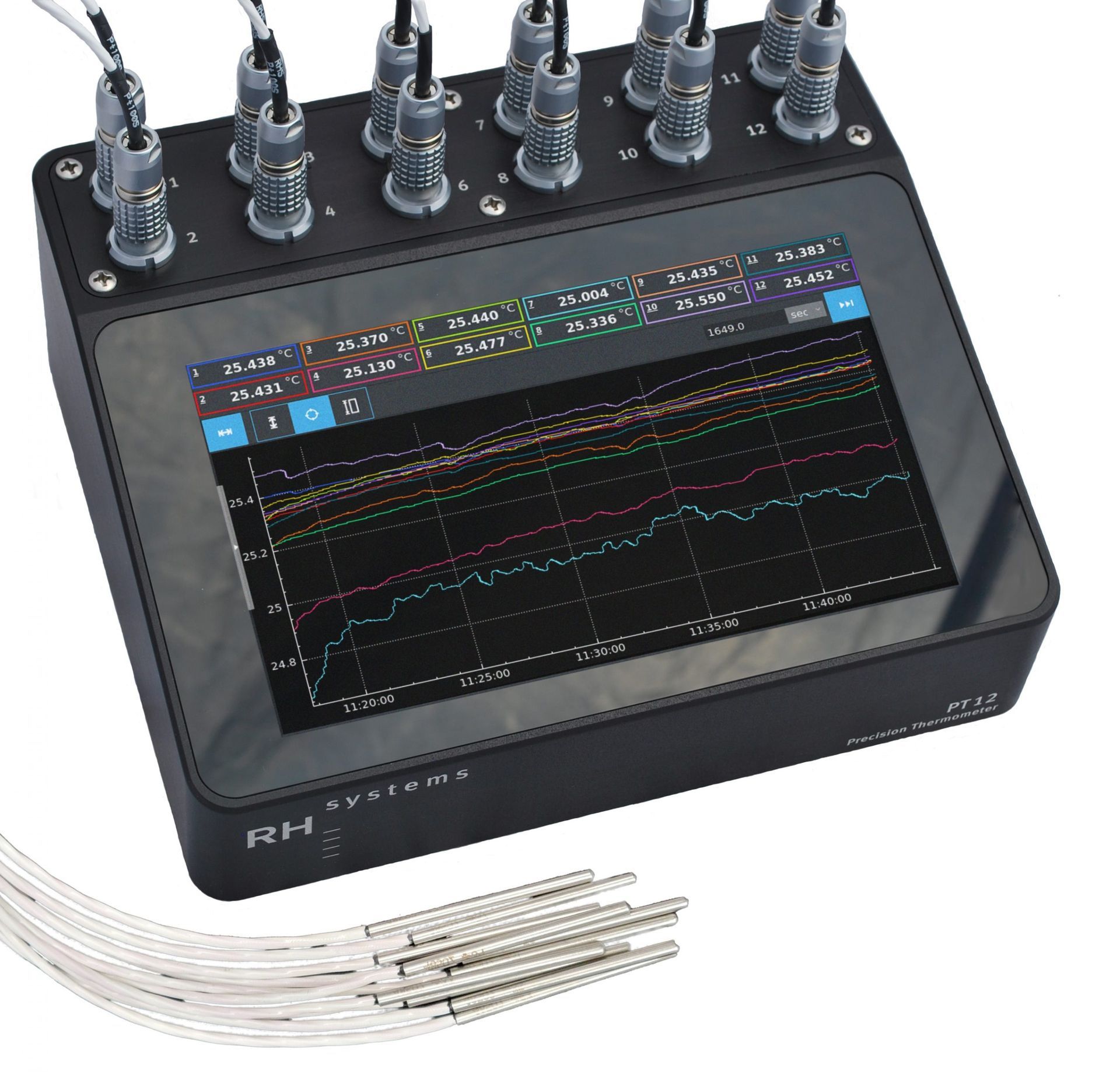

Touchscreen

The PT12 is equipped with a full color touch screen capable of data display in both numeric and graph formats. Graph positioning and scaling uses intuitive pinch/zoom gesturing.

Multiple Coefficient Modes

The supplied software allows each channel to be individually programmed with ITS-90 or Callendar-Van Dusen coefficients for direct conversion of resistance measurements to temperature. The PT12 connects to a PC over the RS-232 interface.

12 channels with measuring current reversal

Using one of three automatic or user selectable measurement currents, the PT12 continuously scans all 12 channels. By using a constant current source with current reversal (switched DC), the PT12 eliminates errors that normally occur with DC measurement methods (thermal voltages). Accuracy is ensured by referencing all measurements to highly stable, temperature-compensated internal reference resistors.

The included software allows each channel to be individually programmed with ITS-90 or DIN/EN 60751 (CvD) coefficients for converting resistance readings to temperature. The PT12 can be connected to a PC via the RS-232 interface.

Supports THERMOtelligent™ Smart 4-wire PRT

THERMOtelligent™ Smart-Platinum Resistance Thermometers save you valuable time and decrease the possibility of measurement errors by eliminating the need to change calibration coefficients in the thermometer readout when temperature probes are changed. An integrated microchip installed in the probe stores calibration coefficients and other information about the PRT. When the PRT is connected to the PT12, it automatically identifies itself and updates the PT12 with the calibration coefficients and other permanent information that is stored in the chip. Since the calibration coefficients are always kept in the THERMOtelligent™ PRT, the PRTs can be moved from channel to channel, or from one THERMOtelligent™-supported readout to another without requiring any reconfiguration. The PT12 also works with any standard 4-wire 100 Ω or 25.5 Ω PRT. In the case of non-intelligent probes, coefficients may be easily entered by the operator through the touch screen. In addition, any 4-wire PRT can be converted to a THERMOtelligent™ Smart-PRT.

data logging

Data may be logged automatically to a USB flash drive. If no drive is detected, data is logged to internal memory and may be copied to a USB drive when inserted at a later time.