Precise Humidity Generation

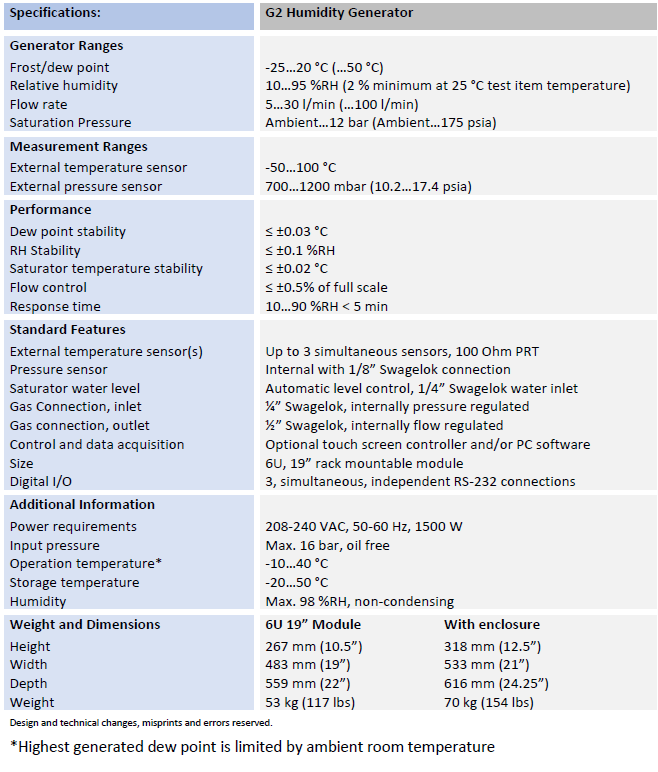

The G2 humidity generator uses the thermodynamic primary method of humidity generation with two pressures and two temperatures, which is also used in many metrology institutes. It delivers a humidified gas stream, accurately controlled to a variety of user selectable humidity parameters such as %RH, dew point, frost point, ppm, or vapor pressure. By accurately measuring the temperature and pressure at the point where the humidified gas is utilized, the G2 automatically adjusts for changes in dynamic conditions such as heat load or ambient pressure variation.

High Flow Capability

With flow rate capacity up to 30 standard liters per minute, the G2 ensures your external volume or test chamber rapidly achieves a stable, homogeneous humidity condition based on your defined RH or dew point setting.

Multiple External Temperatures

Three separate external temperature connections allow for determination of %RH at three completely independent temperatures. By splitting the high-flow gas stream and feeding into three separate chambers, with each chamber controlled at a different temperature, three unique %RH values will be produced. The G2 computes the resulting %RH at each of these three chambers based on the three external temperature measurements.

Alternatively, install up to three temperature probes in one chamber to measure uniformity of temperature and its result on %RH.

Two-Pressure - Two-Temperature Hybrid Technique

Utilizing the uniquely combined benefits of the two-pressure and two-temperature techniques, humidity is generated by fully saturating gas at a known temperature and pressure, then reducing the pressure to a lower value (typically ambient) and cooling or warming to an alternate temperature.

Humidity produced by this hybrid technique is determined from measurements of the temperatures and pressures alone, and does not rely on measurement of the water vapor content of the gas.

With RH Systems’ hybrid humidity generation technique, the G2 is a true humidity reference instrument suitable for high accuracy calibration, product conditioning, and test applications.

Embedded System for Control and Communication

All operations of the G2 are automated by its real-time embedded control system. Its setpoints are commanded and data is retrieved via robust serial communications. There are three fully capable, yet fully independent RS-232 serial ports, allowing for a variety of communication options. For example, up to three PCs could be connected to three temperature chambers and to a single G2 which feeds humidified gas to them all. The three PCs communicate independently with the G2 to retrieve their specific temperature and humidity data.

Simple Application Integration

The G1 is supplied in a 19” rack mountable format for integration within commercially available rack systems. A 19” rack enclosures is available as an option. All electrical, fluid, and pneumatic connections are made at the back panel of the instrument. All fluid and pneumatic connections are via industry standard Swagelok fittings.